Hotrod Home

Kelly Home

Falcon

Mustang

Grandson's Ride

Falcon History

Modifications

Falcon Drivetrain Specs

Mustang 351C Specs

New 351C motor build

Disk brake swap

9" Rear Buildup

Reference

Ford Engine Data

Ford Xmission Data

HydroValve Adjustment

Calculators

Ford/Auto Links

Fun Stuff

Wrecking Yard finds

Wreck of the ol' 351C

Send us a note!

Good Information

The Ford Falcon News

Classic Mustang mail list

Join us online!

|

|

|

Here's the new housing with the brake lines

mounted. I had to drill and tap a 7/16x20 hole for the vent tube, which also

doubles as a hold down for the distribution block. I tack welded a small piece

of 18 gage steel no the driver’s side to help support the line on that side of

the car. |

|

|

|

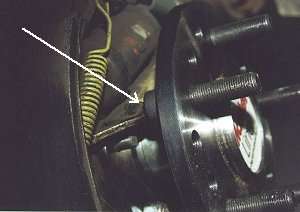

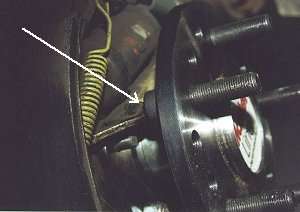

The only thing

left to do to the axles was to put the wheel

studs in the axles. Peyton had pressed the bearings and retainers on for me,

so this was the last prep step for them. The Master Line axles are drilled

for three different bolt circles: 4 ˝, 5 and 5 ˝ inches. The Falcon uses a 4

˝” bolt circle. I treated the installation of the studs as a very critical

step. I cleaned the studs and holes with brake cleaner, then used Loctite 271

on the threads and torqued them to 100 ft/lbs. The object was to help ensure

that the studs would (hopefully) never come loose in normal usage. Imagine

the feeling of loosening a lug and having the wheel stud rotate with it.

Then, imagine a torch closing in on your mags. Ouch! I used 2” studs, which

normally go on front wheels, so I could retain my spiffy chrome lug nuts.

The photo gives you an idea of the beefiness of the Master Line axles compared

to the stock 8". The retaining plate is 3 or 4 times thicker as the stock

plate. The axle diameter at the bearing is larger than a big bearing Ford.

The new bearings use an o-ring seal rather than one located in the housing. The

final problem is pictured on the right. The wheel stud heads came very close

to the shoe spreaders. There appeared to be just enough clearance when the

retaining plates were tightened down, but I ground about .100 off of the

spreaders in that area just for insurance.

I used Richmond’s

recommended break-in procedure: 10 miles “normal” driving, cool down, repeat.

I'd recommend doing this at least four times before driving any real distance.

|

|

References:

Peyton Performance Automotive

422 FM 1493

Waxahachie, TX 75167

(972) 923-1698

Randy’s Ring and Pinion

11630 Airport Road #300

Everett, WA 98204

(800) 292-1031

www.ring-pinion.com |

Richmond Gear

P.O. Box 238

Old Norris Road

Liberty, SC 29657

(803) 843-9231

www.richmondgear.com

Tractech, Inc.

11445 Stephens Dr.

Warren, MI 48090

(810) 759-3850

www.tractech.com |

|

PARTS LIST

|

|

Part Number

|

Description

|

Mfg/Supplier

|

|

Housing

|

72 Ford Torino |

Ford |

|

187SL-17B

|

Detroit Locker |

TracTech |

|

69-0361-1

|

3.70 RIchmond street gears |

Peyton |

|

1K 9F-A

|

9" installation kit |

Randy's Ring & Pinion |

|

SK CS9F

|

Solid pinion spacer |

Randy's Ring & Pinion |

|

SVOM4635A

|

Ford Motorsports U-Joint |

Randy's Ring & Pinion |

|

N/A

|

Mark Williams 31 spline axles |

Peyton |

|

|

Narrow housing |

Peyton |

|

|

ARP ring gear bolts |

Peyton |

|

|

Small housing ends |

Peyton |

|

|

Axle bearings

|

Peyton |

| |

2" axle studs |

Peyton |

| |

Dorman U bolts |

Peyton

|

|

|