Putting the

differential assembly in the case is not a big deal, but measuring for setting

the pinion depth is. The Richmond spec on the gear was 1.040. The basic idea

is to measure the depth of the bore in both the bearing cap and the center

section. The two will probably not be equal. Mine measured 1.457 in the cap

and 1.434 in the case. The difference is .023. Divide by 2 to get .0115, which

I rounded to .012. I used the .012 figure as a “correction factor”. Add .012

to the case bore depth to get 1.446, which would be the true centerline of the

bearing bore. Knowing the offset of the cap mounting face from the bearing bore

centerline, I could then measure from the cap bolt boss to the rear of the

pinion with a depth mike, then add .012 to get the true distance from the

carrier bearing centerline to the pinion. Now, I could just stack some shims,

put them on the pinion support and mount the pinion. I measured the depth and

then added or subtracted shims as necessary. I ended up having to go borrow

some. The final measure was 1.028 from the cap bolt boss to the pinion. Add

.012 and you get 1.040, the exact spec.

With the

heavy math out of the way, I set the backlash. The spec called for .008. The

trick here is to move the ring gear into the pinion using the adjusters. Use the

left adjuster (left as viewed from the pinion flange with the case in the normal

orientation) to put the final squeeze on the bearings for preload since it tends

to move the ring gear away from the pinion. Randy’s documentation says “I set

the carrier bearing preload as tight as I can with a ten or twelve inch long

spanner wrench.”. I made the spanners with twelve inch handles just for that

reason. After about 12 tries, I ended up with .008 backlash. Patience was key

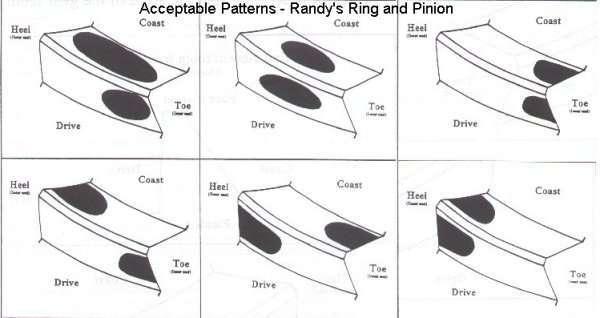

here as a small turn of the adjusters made a big difference. I then checked the

pattern and it looked like it was supposed to according to the sketches from

Randy’s.